Kev siv aluminium extrusion hauv cov khoom tsim thiab kev tsim khoom tau nce ntau hauv xyoo kaum xyoo tsis ntev los no.Raws li tsab ntawv ceeb toom tsis ntev los no los ntawm Technavio, ntawm 2019-2023 qhov kev loj hlob ntawm lub ntiaj teb aluminium extrusion kev lag luam yuav nrawm nrog Compound Annual Growth Rate (CAGR) ntawm yuav luag 4%, ntawm no yog cov lus qhia luv luv ntawm aluminium extrusion yog dab tsi, cov txiaj ntsig nws muaj, thiab cov kauj ruam koom nrog hauv txheej txheem extrusion.

Aluminium Extrusion yog dab tsi?

Aluminium extrusion yog txheej txheem los ntawm cov khoom siv aluminium alloy raug yuam los ntawm kev tuag nrog ib qho kev sib tshuam ntawm qhov profile.Ib tug haib ram thawb lub txhuas los ntawm qhov tuag thiab nws tawm ntawm qhov qhib tuag.Thaum nws ua li ntawd, nws tawm los zoo ib yam li cov tuag thiab raug rub tawm raws lub rooj khiav.Nyob rau theem tseem ceeb, txheej txheem ntawm aluminium extrusion yog yooj yim to taub.Lub zog thov tuaj yeem piv rau lub zog koj siv thaum tuav cov tshuaj txhuam hniav nrog koj cov ntiv tes.

Thaum koj nyem, cov tshuaj txhuam hniav tawm hauv cov duab ntawm lub raj qhib.Qhov qhib ntawm lub raj tshuaj txhuam hniav yeej tseem ceeb ua haujlwm zoo ib yam li extrusion tuag.Txij li thaum qhov qhib yog ib lub voj voog ruaj khov, cov tshuaj txhuam hniav yuav tawm los ua ib qho khoom siv ntev ntev.

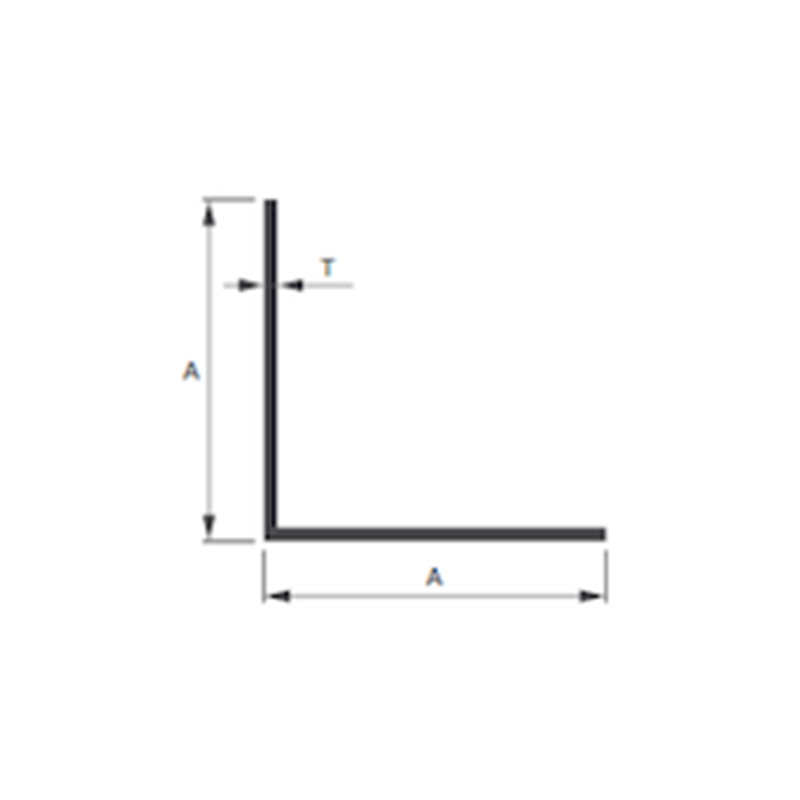

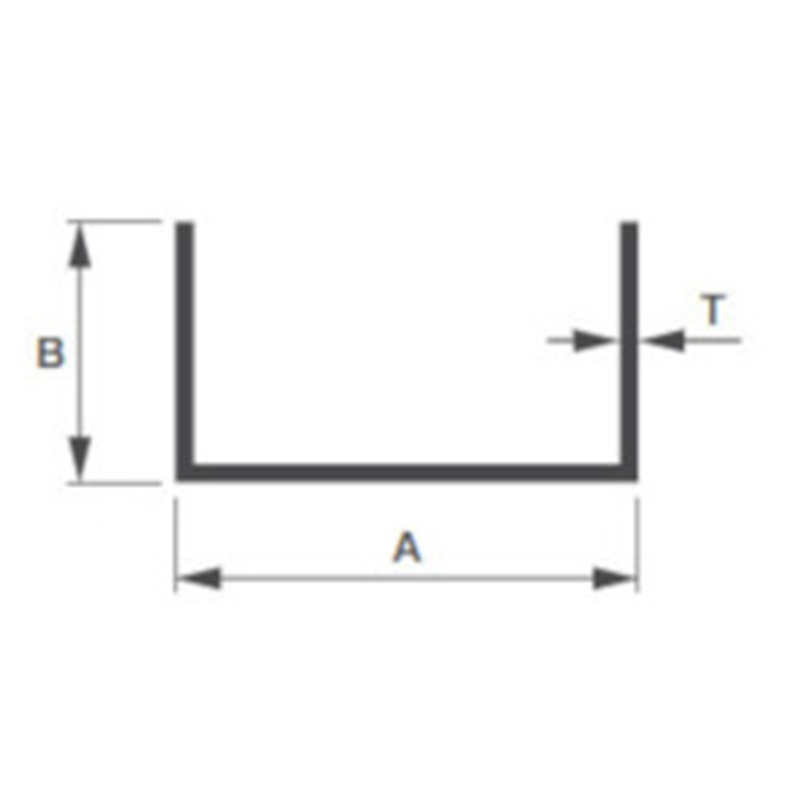

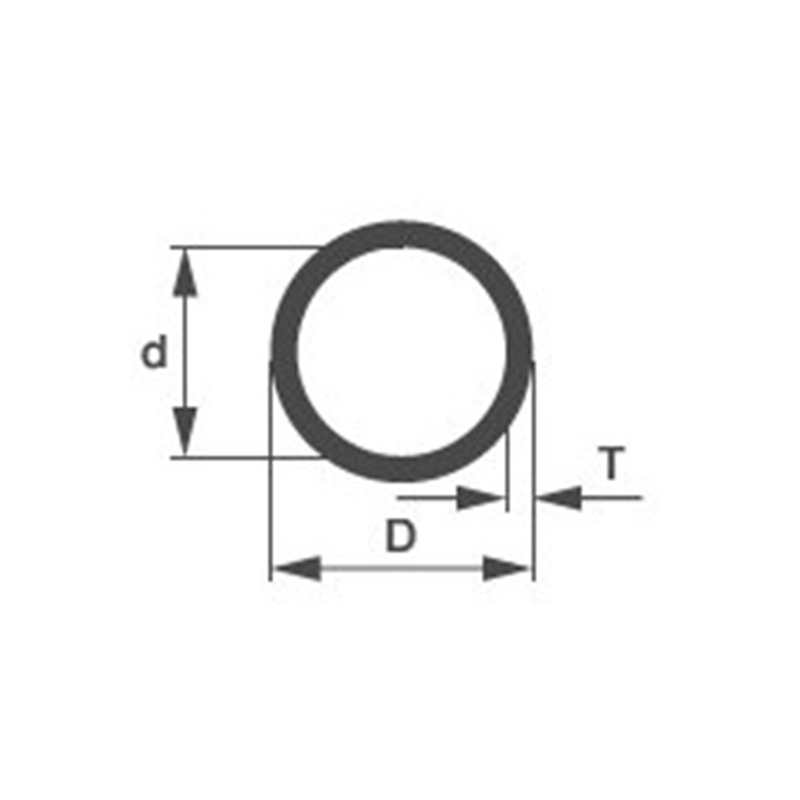

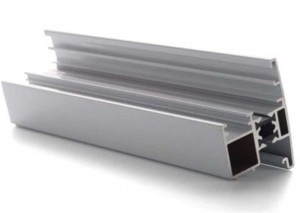

Nov yog qee qhov piv txwv ntawm cov duab uas feem ntau extruded: cov ces kaum, cov kab, thiab cov raj puag ncig.

Ntawm sab laug yog cov duab kos siv los tsim cov tuag thiab sab xis yog renderings ntawm qhov tiav aluminium profiles yuav zoo li.

Daim duab: Aluminium Angle

Daim duab: Aluminium Channel

Daim duab: Round Tube

Feem ntau, muaj peb pawg tseem ceeb ntawm cov duab extruded:

1. Khoom, tsis muaj cov voids los yog qhib (piv txwv li ib tug pas nrig, beam, los yog kaum).

2. Hollow, nrog ib lossis ntau qhov khoob (piv txwv li square lossis lub raj raj)

3. Ib nrab hollow, nrog ib feem ntawm qhov khoob (piv txwv li "C" channel nrog qhov sib txawv nqaim)

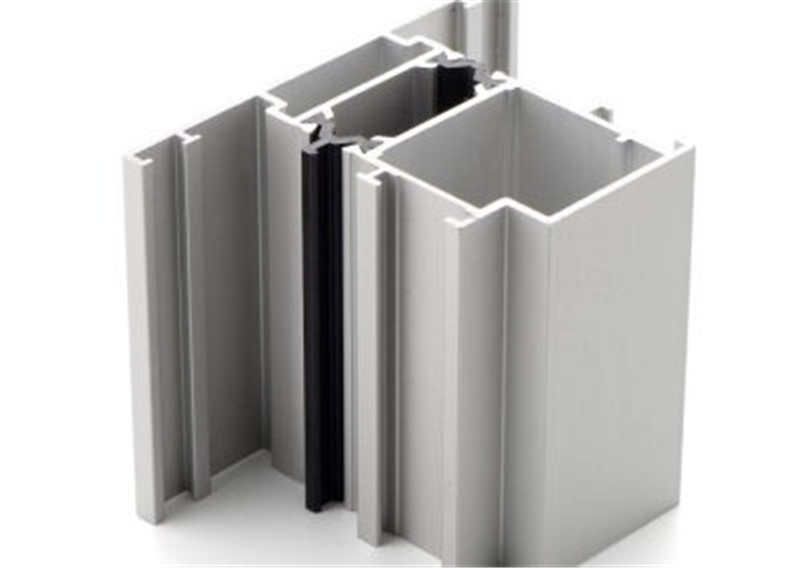

Extrusion muaj ntau daim ntawv thov thoob plaws ntau yam kev lag luam, suav nrog kev tsim vaj tsev, tsheb, electronics, aerospace, zog, thiab lwm yam lag luam.

Hauv qab no yog qee qhov piv txwv ntawm ntau cov duab uas tau tsim los rau kev lag luam architectural.

Aluminium Extrusion txheej txheem nyob rau hauv 10 kauj ruam

Kauj Ruam 1: Lub Extrusion Tuag yog npaj thiab txav mus rau Extrusion Xovxwm

Kauj Ruam 2: Ib qho Aluminium Billet yog Preheated Ua ntej Extrusion

Kauj Ruam 3: Lub Billet raug xa mus rau Extrusion Xovxwm

Kauj Ruam #4: Lub Ram thawb cov khoom siv Billet rau hauv lub thawv

Kauj Ruam 5: Cov Khoom Siv Extruded Tawm Los Ntawm Kev Tuag

Kauj Ruam #6: Extrusions yog coj raws li lub rooj Runout thiab quenched

Kauj Ruam #7: Extrusion yog sheared rau lub rooj ntev

Kauj Ruam 8: Extrusion yog txias rau chav kub

Kauj Ruam 9: Extrusions raug tsiv mus rau lub stretcher thiab stretched rau hauv Alignment

Kauj Ruam #10: Extrusions raug txav mus rau qhov kawg pom thiab txiav kom ntev

Thaum extrusion tiav lawm, profiles tuaj yeem kho cua sov los txhim kho lawv cov khoom.

Tom qab ntawd, tom qab kev kho cua sov, lawv tuaj yeem tau txais ntau qhov chaw tiav los txhim kho lawv cov tsos thiab kev tiv thaiv corrosion.Lawv kuj tuaj yeem raug tsim ua haujlwm los coj lawv mus rau lawv qhov kawg qhov ntev.

Kev kho cua sov: Txhim kho cov cuab yeej cuab tam

Alloys nyob rau hauv 2000, 6000, thiab 7000 series tuaj yeem kho cua sov los txhim kho lawv qhov kawg tensile lub zog thiab tawm los kev ntxhov siab.

Txhawm rau ua tiav cov kev txhim kho no, cov ntaub ntawv raug muab tso rau hauv qhov cub uas lawv cov txheej txheem kev laus nrawm nrawm thiab lawv tau coj mus rau T5 lossis T6 tempers.

Lawv cov khoom hloov li cas?Ua piv txwv, tsis kho 6061 txhuas (T4) muaj lub zog tensile ntawm 241 MPa (35000 psi).Thaum tshav kub kub kho 6061 txhuas (T6) muaj lub zog tensile ntawm 310 MPa (45000 psi).

Nws yog ib qho tseem ceeb rau cov neeg siv khoom kom nkag siab txog lub zog xav tau ntawm lawv qhov project los xyuas kom meej qhov kev xaiv zoo ntawm alloy thiab temper.

Tom qab kho cua sov, profiles kuj tuaj yeem ua tiav.

Surface Finishing: Txhim kho qhov tshwm sim thiab kev tiv thaiv corrosion

Extrusion tuaj yeem ua tiav thiab tsim nyob rau hauv ntau txoj kev

Ob lub laj thawj tseem ceeb los xav txog cov no yog tias lawv tuaj yeem txhim kho cov tsos ntawm aluminium thiab tuaj yeem txhim kho nws cov khoom corrosion.Tab sis muaj lwm yam txiaj ntsig thiab.

Piv txwv li, cov txheej txheem ntawm anodization thickens cov hlau ib txwm ua oxide txheej, txhim kho nws cov corrosion kuj thiab kuj ua rau cov hlau ntau resistant rau hnav, txhim kho deg emissivity, thiab muab ib tug ntxeem tau nto uas tuaj yeem txais cov xim sib txawv.

Lwm cov txheej txheem tiav xws li kev pleev xim, hmoov txheej, xuab zeb blasting, thiab sublimation (los tsim cov ntoo zoo), tuaj yeem ua tiav thiab.

Tsis tas li ntawd, muaj ntau yam kev xaiv fabrication rau extrusion.

Fabrication: Tau Txais Qhov Kawg Dimensions

Fabrication xaiv tso cai rau koj kom ua tiav qhov kawg qhov ntev uas koj tab tom nrhiav rau hauv koj cov extrusion.

Profiles tuaj yeem raug punched, drilled, machined, txiav, thiab lwm yam kom phim koj cov specifications.

Piv txwv li, cov fins ntawm extruded aluminium heatsinks tuaj yeem hla machined los tsim tus pin tsim, los yog cov ntsia hlau qhov tuaj yeem drilled rau hauv cov qauv.

Txawm hais tias koj xav tau, muaj ntau yam kev ua haujlwm uas tuaj yeem ua tiav ntawm aluminium profiles los tsim kom haum rau koj qhov project.

Aluminium Extrusion yog txheej txheem tsim khoom tseem ceeb Yog tias koj xav paub ntxiv txog yuav ua li cas txhawm rau txhim kho koj tus qauv tsim rau txheej txheem extrusion, pls xav tiv tauj nrog YSY kev muag khoom thiab pab pawg engineering, peb npaj txhij rau koj txhua lub sijhawm koj xav tau.

Lub sij hawm xa tuaj: Plaub Hlis-05-2022